Engineering Plastics

Polybutylene Terephthalate (PBT)

Introductions & Properties:

PBT thermoplastic polyester resins are high performance plastic molding resins which are based on polybutylene terephthalate (PBT) polymers. By adding reinforcing agents and tougheners, the inherent low creep, dimensional stability and good electrical properties of PBT can be augmented to provide a family of molding resins with exceptional strength, stiffness and toughness. Alloying with other polymers and selecting the proper reinforcement technology can improve dimensional stability and surface appearance. PBT is offering superior performance in Flow, Flatness & Toughness.

Industry Wise Applications:

- Exterior Body Panels & Glazing

- Back Lites, Door Panels, Fenders, Fixed Glazing, Panoramic Roofs, Roof Modules & Tailgates

Exterior Components, Trims & Accessories:

- Appliques, Cowl Vent Grilles, Door , Handles, Front Grilles, Mirror Systems, Roof Racks, Running Boards, Spoilers, Tank Flaps & Wheel Covers.

Lighting:

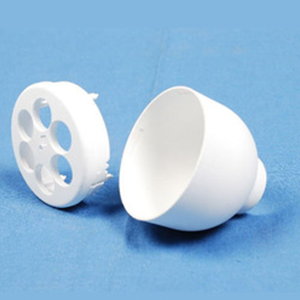

Fog Lamp Housings, Fog Lamp Lenses, Fog Lamp Reflectors & Housings, Headlamp Bezels - Base Coated or Painted, Headlamp Bezels - Direct Metalized, Headlamp Bezels - Molded-in-Color, Headlamp Housings, Headlamp Inner Lenses, Headlamp Lenses, Headlamp Reflectors, Lamp Support Bracket, Projector Lamp Reflectors, Projector Lens Holders, Rear Combination Lamp Housings, Rear Combination Lamp Lenses, Signal Lighting & Tail Lamp Inner Lenses.

Power Train:

Air Intake, Automotive Gears, Automotive Wire Coating, Brackets, Electronic Housings, Fuel System Components, Pulleys, Sensors, Throttle Bodies, Transmissions & Valve Rocker Covers.

Structures & Interiors:

Composite Headliners, FMVSS Energy Absorption Systems, Front end modules, Instrument Panels & Interior Trim, Load Floors, Pedestrian Energy Absorption Systems Resin Headliners & Storage Bins.

Polymide 6, 6.6 (Nylon 6, 6.6)

Polyamide is a polymer containing monomers of amides joined by peptide bonds. They can occur both naturally and artificially, examples being proteins, such as wool and silk, and can be made artificially through step-growth polymerization, examples being nylons, aramids, and sodium poly (aspartate).

Due to their outstanding properties these material have become indispensable in almost all fields of engineering for the most varied components and machine parts, as high-quality electrical insulating materials and for many other special applications. Nylon is exceptional for its high mechanical strength, rigidity and thermal stability. Moreover, Nylon affords good impact resistance even at low temperatures, advantages sliding friction properties and problem-free processing. It is mainly used in Automobile, Engineering, Electrical, Electronics & Textiles industries.

Injection Molding:

- A L/D ratio of 18 –22 is recommended.

- Melt temperature : 240- 270°C.

- Min temperature : 55 – 80°C.

Extrusion:

- Only highly viscous grades can be processed by extrusion.

- A three- sections screw with a L/D ratio of 20 – 30 is recommended.

- The processing temperature should lie between 240 and 270°C.

Engineering Industry:

Better functional properties at low cost, metal components are being replaced by Polyamide 6. Applications: Gears / Bushes / Cams, Impeller Fans, Ropeway Pulley, Coupling Components, Roller, Castors, Nylock Nut/Washers, Idler Seals, Water Meter Housing, Insulator Liners.

Textile Industry:

Higher abrasion resistance, silent running, high impact resistance and the need for anti-static surface, make Polyamide 6 a unique choice over the materials. Applications: Drafting spacer, Picker Bush Bobbins, Drive Pulley, Ring Tubes/Bobbins, Gears/Bushes, Magnetic Holder, Shuttles/Pirns, Steamable ring tubes, Tensions Craddle, Yarn Separators.

Automobile Industry:

Exterior, under bonnet and near the engine applications. Easily paintable with low-cost bake paints and can be given a finish similar to metal components. Applications: Radiator Fan, Radiator Grill, Head/Tail Lamp Housing, Speedometer Gears, Door Handles, Fuel oil filter housing.

Electrical/ Electronic Industry:

Polyamide 6 resins, due to a combination of excellent electrical properties viz., insulation/tracking resistance, di-electric strength toughness and flame retardant characteristics are fast replacing conventional materials. Applications: Circuit Breaker, Battery Casing, Switch / Switch Parts, Terminal / Connectors, Carbon Brush Holder.

Poly Acetal (POM)

Polyoxymethylene (POM), also known as acetal, polyacetal, and polyformaldehyde, is an engineering thermoplastic used in precision parts that require high stiffness, low friction and excellent dimensional stability. POM is a lightweight, low-friction, and wear-resistant thermoplastic with good physical and is often marketed and used as a metal substitute.

Poly Methyl Methacrylate (PMMA)

Shatter-resistant or lighter alternative to glass, Poly Methyl Methacrylate also known as PMMA/Acrylic/Acrylic Glass/Acrylic Resin is a transparent thermoplastic. Chemically, it is the synthetic polymer of Methyl Methacrylate. Where extreme strength is not required, PMMA can be used as an economical alternative to Polycarbonate (PC).Where extreme strength is not required, PMMA can be used as an economical alternative to Polycarbonate (PC).

Polycarbonate(PC)

Polycarbonate is a particular group of thermoplastic polymers. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications. This polymer is highly transparent to visible light and has better light transmission characteristics than many kinds of glass. Polycarbonate is a very durable material & although it has high impact-resistance, it has low scratch-resistance.