Poly Methyl Methacrylate (PMMA)

Introduction & Properties

Poly Methyl Methacrylate (PMMA), commonly known as acrylic, is a high-performance transparent thermoplastic renowned for its durability, lightweight structure, and shatter resistance. As a superior alternative to glass, PMMA offers exceptional optical clarity, excellent UV resistance, and outstanding weather durability, making it ideal for both indoor and outdoor applications. Its versatility and ease of fabrication make it a preferred material across various industries.

Key Benefits:

High Transparency –

Exceptional optical clarity, transmitting up to 92% of visible light.

Shatter Resistance -

Stronger and safer than glass, reducing breakage risks.

UV & Weather Resistance -

Withstands prolonged exposure to sunlight without yellowing.

Lightweight –

Weighs significantly less than glass, making it easier to handle and install.

Easy Fabrication –

Can be molded, cut, and thermoformed into various shapes.

Industry Applications :

Automotive:

Headlamp lenses, sunroofs, instrument panels.

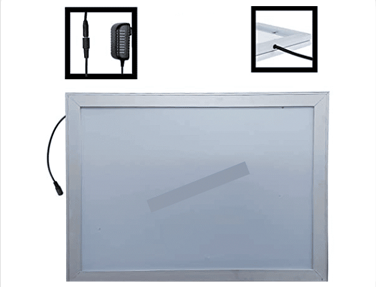

Electronics :

Protective screens, touch panels, device casings.

Construction :

Roofing panels, windows, skylights, bulletproof glazing.

Displays & Signage :

Advertising boards, LED light diffusers, retail displays.

Medical & Healthcare :

Optical lenses, medical device components, incubators.

Why Choose PMMA?

PMMA is not just a durable and aesthetic material—it is also an eco-friendly choice. It can be recycled and repurposed, making it a sustainable option for various applications. Whether you need high optical performance, impact resistance, or weatherproofing, PMMA is a reliable solution.